- Chain (Main Load-Bearing Component)

The chain serves as the sling’s primary load-bearing structure, directly supporting the weight of lifted objects. It is typically manufactured from high-strength alloy steel—this material balances durability and tensile strength, making it suitable for heavy-duty use. The most common specifications in industry are G80 and G100, which represent different strength grades; higher numbers indicate greater load-bearing capacity, allowing users to select based on specific lifting requirements.

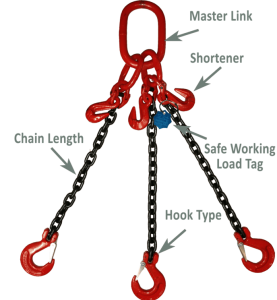

- Hook (Lifting Connection Component)

The hook acts as the critical connection point between the sling and the lifted object, enabling secure attachment. It comes in various types to adapt to different load shapes and lifting scenarios:

- Eye hooks: Feature a closed, loop-like design, ideal for connecting to shackles or other lifting hardware.

- Grab hooks: Have a narrow, open slot, designed to “grab” specific links of the chain, offering flexibility for adjusting sling length.

- Terminal Accessories (Stability & Safety Enhancement)

This category includes auxiliary components that boost the sling’s overall stability and safety, preventing accidental disconnection or load slippage. Common types are:

- Connecting rings: Used to join different segments of the chain or attach hooks, ensuring a smooth force transfer.

- Catchers (or safety latches): Installed on hooks to keep the load securely in place, preventing it from slipping out during lifting.

- Locks: Add an extra layer of security, locking connections (e.g., between hooks and rings) to avoid loosening under vibration or uneven loads.